Shanghai, China

30 Sets/Year

T/T, Western Union, Paypal, Money Gram

BNF60A

Pressure

Pneumatic Lifting

Rotary

Tube

Soft-Tube

Bnf60A

30-60PCS/Min

Paste , Cream

Aluminum Tube or Other Metal Tube

Hot Air Heating for Inside Sealing

10-35mm for Metal Tube or Plastic Tube

1-150 for Metal Tube or Plastic Tube

1%

1.1kw

0.4-0.6MPa

BSIT

Export Standard Wooden Case

Meet GMP Standard

Made in China

8422303090

Volumetric Filling Machine

Automatic

Paste

Multi-Head

Single-Room Feeding

Capacity Cup

| BSNF-60A | |||

| Configuration Standard | Technical Parameters | Remarks | |

| Infrastructure | |||

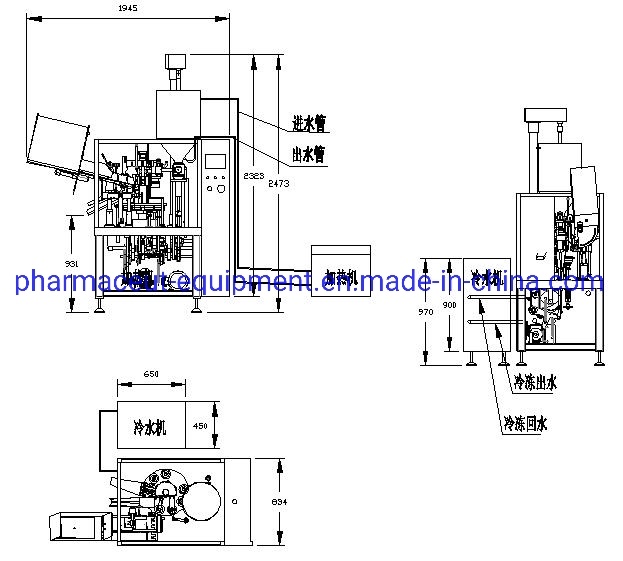

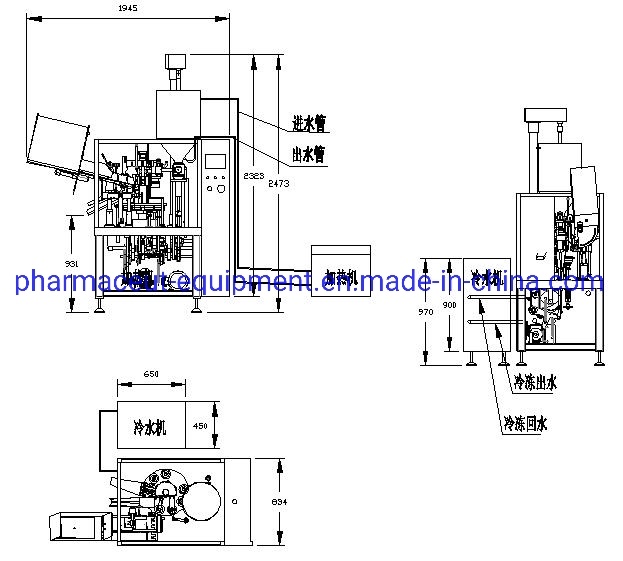

| Main Machine Landing Area | (about) 2m2 | ||

| Working Area | (about)12m2 | ||

| Water Chiller Landing Area | (about)1m2 | ||

| Working Area | (about)2m2 | ||

| Whole Machine (L×W×H) | 1950×1000×1800mm | ||

| Integrated Structure | Union mode | ||

| Weight | (about)850Kg | ||

| Machine case body | |||

| Case Body Material | 304 | ||

| Opening Mode of Safety Guard | Handle Door | ||

| Safety Guard Material | Organic Glass | ||

| Frame Below Platform | Stainless Steel | ||

| Case Body Shape | Square-shape | ||

| Power, Main Motor etc. | |||

| Power Supply | 50Hz/380V 3P | ||

| Main Motor | 1.1KW | ||

| Hot Air Generator | 3KW | ||

| Water Chiller | 1.9KW | ||

| Jacket barrel heating power | 2 KW | Optional Additional cost | |

| Jacket barrel blending power | 0.18 KW | Optional Additional cost | |

| Production Capacity | |||

| Operation Speed | 30-50/min/max | ||

| Filling Range | Plastic/laminated tube 5-250ml | ||

| Suitable Tube Length | Plastic/laminated tube 50-210mm | Pipe length more than 210mm should customize | |

| Suitable Tube Diameter | Plastic/laminated tube 13-50mm | ||

| Pressing Device | |||

| Appliance | Aluminum tube |

| Range of tube diameter | 10-35mm for metal tube |

| Range of filling volume | 1-150 for metal tube |

| Productivity | 30-60PCS/min |

| Filling error tolerance | 1% |

| Motor | 1.1kw |

| Air pressure | 0.4-0.6Mpa |

| BSNF-60A | |||

| Configuration Standard | Technical Parameters | Remarks | |

| Infrastructure | |||

| Main Machine Landing Area | (about) 2m2 | ||

| Working Area | (about)12m2 | ||

| Water Chiller Landing Area | (about)1m2 | ||

| Working Area | (about)2m2 | ||

| Whole Machine (L×W×H) | 1950×1000×1800mm | ||

| Integrated Structure | Union mode | ||

| Weight | (about)850Kg | ||

| Machine case body | |||

| Case Body Material | 304 | ||

| Opening Mode of Safety Guard | Handle Door | ||

| Safety Guard Material | Organic Glass | ||

| Frame Below Platform | Stainless Steel | ||

| Case Body Shape | Square-shape | ||

| Power, Main Motor etc. | |||

| Power Supply | 50Hz/380V 3P | ||

| Main Motor | 1.1KW | ||

| Hot Air Generator | 3KW | ||

| Water Chiller | 1.9KW | ||

| Jacket barrel heating power | 2 KW | Optional Additional cost | |

| Jacket barrel blending power | 0.18 KW | Optional Additional cost | |

| Production Capacity | |||

| Operation Speed | 30-50/min/max | ||

| Filling Range | Plastic/laminated tube 5-250ml | ||

| Suitable Tube Length | Plastic/laminated tube 50-210mm | Pipe length more than 210mm should customize | |

| Suitable Tube Diameter | Plastic/laminated tube 13-50mm | ||

| Pressing Device | |||

| Appliance | Aluminum tube |

| Range of tube diameter | 10-35mm for metal tube |

| Range of filling volume | 1-150 for metal tube |

| Productivity | 30-60PCS/min |

| Filling error tolerance | 1% |

| Motor | 1.1kw |

| Air pressure | 0.4-0.6Mpa |